All Blogs, Priming and Protecting, Weatherproofing

Which Metal Primer to Use and When?

Which metal primer should I use?

A question we’re often asked here at Palatine Paints, so of course it’s a great opportunity to explain. Before explaining about metal primers however, we need to briefly address another question: “What’s the difference between undercoat and primer?”

Undercoats and primers serve different purposes:

What’s an Undercoat?

- Serves as a base layer to prepare your surface ready for its finish coat

- Helps you cover any inconsistencies in your surface

- Gives you a neutral surface if you’re painting over a particularly strong colour

- Note…an undercoat may follow application of a primer in some circumstances (which hopefully we clarify below)

What’s Primer?

A primer usually acts as some kind of protective or preparatory coating. Different primers can have different purposes. This often depends on the surface to which it is being applied. In general a primer does one or more of the following:

- Provides a binding medium for subsequent coatings

- Prevents corrosion or inhibits rust in ferrous metals

- Is used over porous materials to ensure effective application and drying of subsequent coats

- Provides additional protection to a surface

- Helps paint adhere to non-porous (shiny etc) surfaces to allow subsequent coats to stick

- Can act as a barrier between the surface and finish coat, for example were surface is heated (such as hot water pipes)

- Helps durability

- Can create a barrier where a surface has chemical properties (such as high alkaline content) which might react and affect application of the top coat

So primers and undercoats do serve different purposes. You may find some coatings that are suitable as both primer and undercoat for certain jobs or surface types.

Which Primer or Undercoat do I need then? This it depends on:

- Your surface and what it’s made of

- Whether it has been painted or treated previously

- The quality of the surface

- What you hope to apply as a finish coat

Here we’re dealing with metal primers. As an industrial paint manufacturer, we make a variety of durable primers for metal, so we do know what works and what doesn’t. We’ll be looking at primers for other surfaces in future blogs.

Which Primer for Which Metal Type?

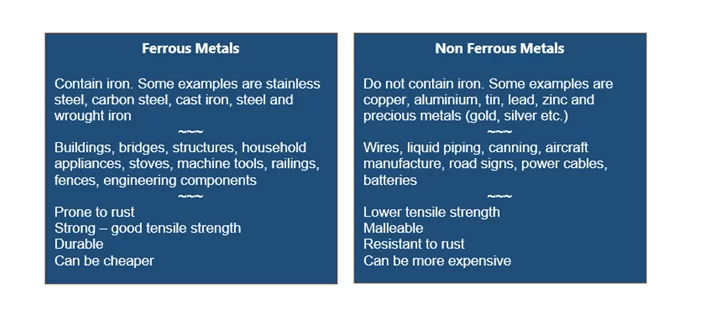

What is the best primer for metal? For paint purposes you can usually put your metals into the basic two categories: Ferrous or non-ferrous. For a quick way to distinguish…ferrous metals contain iron and non-ferrous metals do not.

Ferrous Metals

Ferrous metals contain iron and are pretty much anywhere you look. Examples are stainless steel, carbon steel, cast iron, steel and wrought iron. Known for their tensile strength ferrous metals are widely are used in architecture, engineering and industry – from large structures like bridges, to engines, household appliances and small engineering components.

Many ferrous metals are also prone to rust due (the rust level will depend on the amount of iron and whether other metals such as chromium have been added).

Non Ferrous Metals

Non ferrous metals don’t contain iron. Some examples of widely used non ferrous metals are: copper; aluminium; tin; lead; zinc; titanium as well as precious metals (gold, silver and platinum etc). Non ferrous metals are used because of properties such as malleability, low weight, good conductivity and high resistance to corrosion/rust.

Non ferrous metals can be found used in many areas including wiring (copper), some pipework, aircraft manufacture (aluminium) and construction (lead).

Brief summary of some differences between ferrous and non ferrous metals

What Metal Primer do I use?

You may not need a primer at all. If a metal surface is previously coated and is in good condition, a good quality topcoat may be all you need (there are some examples in our industrial topcoats section). If your metal surface has any of the following conditions then you will need a primer:

- Shiny or new unsealed metal

- Likely to be exposed to humid, cold or demanding (in fact any) weather conditions

- Is in poor condition

- The right metal primer will help prevent corrosion and rust (see more about rust here) while ensuring the top coat adheres and does not peel or flake off.

Here are some metal primers with details of what they’re used for:

Red Oxide Primer

Red oxide primer protects against rust and corrosion. Use it on ferrous metals likely to be exposed to the elements especially cold air, damp and humidity. It is widely used in the industrial and agricultural industries for structural steel work, outdoor equipment and railings, gates etc.

It gives a layer of protection before a top coat is applied and will still adhere to surfaces that already have traces of rust.

As its name suggests, red oxide primer comes in ‘red’ (origins go back to ‘red lead’ paint). It is now lead free and here at Palatine Paints we also make it in grey and black.

Etching Primer

Etching Primer is used on non ferrous and galvanised surfaces to help with adhesion of subsequent coats. Etching primer effectively ‘eats into’ the ‘galv’ (without completely removing all the zinc protection of course), to prime and protect the surface at the same time.

It contains acid which etches the surface (creating a physical and chemical bond) and promotes adhesion of subsequent coats.

You may be limited in your choice of subsequent coats when using an etching primer, so check first. It’s commonly used on railings, lamp posts and in vehicle repairs etc.

Mordant Solution

Mordant solution is commonly used for treating galvanised steel and zintec sheeting before painting. It contains phosphoric acid which reacts with the ‘galv’ and turns it black. This helps to indicate which parts have been treated. Mordant solution effectively “firs up” the metal surface to aid adhesion of subsequent top coats. Treatment with mordant solution allows a wider choice of primers/top coats than etching primer. Mordant solution is also known as T Wash.

Zinc Rich Primer

Zinc rich primer is a cold galvanising paint, some times you may hear it referred to as ‘galvafroid’ which is a brand name. Used on iron or steel Palatine’s zinc rich primer (Carbogalv) can actually be used as a self-finish coating. With a high zinc content it makes a durable, extremely rust inhibiting primer. The zinc is what helps to protect the iron/steel.

Because it is more reactive than iron, it effectively sacrifices itself so that it oxidises in preference to the iron. It is used for the protection of structural steelwork, agricultural and construction plant and machinery. Other uses include: gates; railings; iron; pipework and the rust prevention of in-situ welding work.

Carboxide Metal Primer

Our Carboxide Metal Primer is an anti-corrosive primer for iron and steel. It can be used with a variety of topcoats so is a good choice for metal gates, metal doors, architectural ironwork etc. The higher level of modified zinc phosphate content means that superior, longer term protection is provided. If you’ve been asked to source a zinc phosphate primer, this is what you’ll need. It can be used even where ‘gingering’ has already begun. A choice of red, white or grey colour gives you several options to match your top coat. We have a variety of suitable top coats for use with Carboxide metal primer. Go to product page or read on.

Fast Dry Metal Primer

Fast dry metal primer is an anti corrosive, solvent based metal primer for ferrous metals including mild steel, carbon steel, stainless steel, cast and wrought iron. Palatine’s version is specially formulated for spray application and is touch dry in 15 minutes. Sometimes you’ll find this kind of primer referred to as cellulose primer.

This primer gives long term protection due to modified zinc phosphate and is an excellent primer for our Fast Dry Gloss or Semi-Gloss top coat. Fast dry metal primer is ideal for situations where you need to apply a primer quickly and easily.

Contacting us is easy!

Email: [email protected]

Call Us: 01942 884 122

Contact form: https://www.palatinepaints.co.uk/contact-us

As always, we welcome comments below. We also have our online chat manned each weekday during working hours or call/email us!

I am restoring some older cars. I plan to strip everything down to bare metal. If pitting or small dings need body filler, does that mean I cannot use the self etching primer ? or would the primer have to be sanded away, filled and then recoated with another primer

I’ve been browsing some tips. This will be useful when I paint my fences. Thanks!

I need to fully restore an 18th century painted vertical sundial made of lead, measuring about 500 x 500 mm.

Assuming I can remove previous paint layers, what paint should I use for primer, undercoat and topcoat? The sundial faces almost south, so is exposed to strong sunlight year-round.

Hi, I want to do some rust treatment on my van. I know the metal is pitted, and I won’t be able to go back to bare metal.

Do I use a rust converter or remover? And what primer would you advice me to use to keep the rust at bay. I live by the sea.

I welcome your advice!

A convertor is a good quick fix option and is also good for the hard to reach areas. A rust inhibitive & anti corrosive primer like our Carboxide Metal Primer can then be applied and followed with a protective gloss (our two hour gloss is a possible choice). A rust remover will help you take it right back to the metal, some additional work with a wire brush will still be required, you can then use the same approach with primer/topcoat. A rust remover is quite harsh so isn’t always the right choice for soft or damaged metal.

thanks for the posts very useful

THIS IS NOT A COMMENT, IT IS A QUESTION.

I have completely stripped my “up and over” garage door, which I think is made of aluminium. (How can I check?)

The door is to be repainted white, so what would be the best primer to use and what sort of overcoat would you recommend?

If the door has been stripped completely back to the bare metal and it is aluminium, an etching primer would be the best option, followed by Palatine Professional gloss (truglos) or satin in white.

Hi i’m looking for an easy to apply primer for a metal railing. The last one I got had a gluey feel when applying to metal, making the job hard.

Thanks John

Either grey/red/white oxide primer or our metal primer would be suitable.

Which is best for ferrous metal, red oxide or zinc primer

Hi Bill. They offer varying levels of protection: Red Oxide Primer is a good rust inhibiting primer that gives a layer of protection to metal before overcoating; A zinc phosphate primer like our Carboxide Metal primer is higher build and contains zinc phosphate which provides additional anti corrosive properties; Zinc Rich Primer (such as our Carbogalv) has an even higher concentration of zinc (95%) which is what protects the metal against both rust and corrosion. Zinc Rich primer can also be used as a self finishing coating. Zinc rich primer would be more expensive for large areas so you need to think about how much protection you really need. Have a look at our individual product listings in our Primers Section for more detailed information on each product.

Sir Red oxide can we apply as primer for aluminium paints

What kind of aluminium paint are you going to be using? The red oxide primer is suitable for using under our Carboxide Bright Aluminium Paint

Hi

Can Red oxide primer use on painted area of iron gate? Or just area of bare rusty metal?

This primer can be used on painted areas and bare metal. If rust is an issue we advise considering a rust converter or remover first

Thank you for shining some light onto this complex subject. Unfortunately I am still at a loss with my specific question:

Is a primer that is recomended for stainless steel also good for an aluminium surface, such as a bikeframe?

For an aluminium surface we would recommend using an etching primer or mordant solution, followed by a base coat/primer (like our Carboxide oxide primer) and a suitable top coat like Two hour gloss.