FREE SHIPPING AVAILABLE ON ORDERS OVER £75.00*

ArmourFlex UV Protection Oil

A blend of oils, waxes and resins that protects wooden cladding and other external wood against weathering and UV damage.

- Protects high value cladding from UV degradation

- Retains original wood colour

- Extends wood life

- Significantly enhances water shedding properties

£19.04 – £60.39

Stay Social. Connect with us.

Product Description

ArmourFlex UV Protection Oil is a blend of natural oils, resins and waxes that protects wooden cladding and other external wood against weathering and UV damage. The oil also contains ingredients to help prevent the growth of mould, algae and fungi.

This oil is suitable for both softwood and hardwood, providing a water repellent finish that is resistant to flaking, cracking, blistering and peeling. ArmourFlex Protection Oil prevents cladding and external wood from needing repairs or replacement due to UV or water damage.

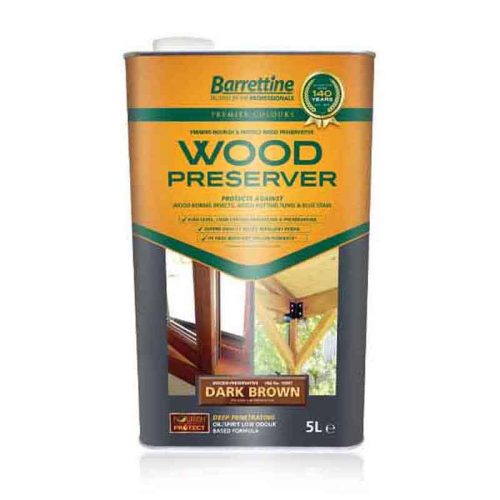

When applying to unpreserved wood, use Barrettine Universal Wood Preserver as primer before application. This provides additional protection to the cladding against wet rot and wood boring insects, further prolonging the lifespan.

If the wood has already begun to grey from UV exposure, apply Barrettine Wood Reviver before this cladding oil. This will restore the wood to it’s original colour, with the oil preventing future discolouration and damage due to sun exposure.

If you have any queries regarding this product, our technical team are happy to help. We are available by phone or web chat during our opening hours, and respond to emails sent outside of these hours the next morning.

Application Conditions

Stir thoroughly with a flat-bladed paint stirrer before and during application, ensuring good ventilation (preferably apply outside). Protect areas not intended to be coated with impermeable sheeting/masking tape and if in doubt, confirm suitability before use.

The moisture content of the wood should not be above 20% and can be checked using a handheld moisture meter. The temperature during application and drying must be between 5-30°C, with no rain forecast within 12 hours. The relative humidity must be below 80% and ideally below 60%. If heavy rain has occurred recently, wait a minimum of 2 days for wood to thoroughly dry throughout. Application during cold or damp conditions will impact drying and may lead to a milky/hazy appearance as moisture becomes trapped in the finish.

Application Process

Apply 2-3 coats. Decant the product as needed and apply evenly using a high-quality brush and/or roller. The first coat can be applied generously until no further product will absorb into the wood. Subsequent coats should be applied sparingly. Beyond 2 coats, the gloss level will increase.

The first coat on bare/weathered wood will absorb far more product than subsequent coats. Product can be re-coated after approximately 4 hours but will require a minimum of 10 hours to develop maximum water repellence. Protect from rain/frost until dry, to avoid damp becoming trapped within the finish.

Coverage – approximately 15 – 20m² per litre, though this depends on the type of wood.

For full details of preparation based on the current state of the wood, please see the Technical Data Sheet.

Product Documents

Surface Preparation

Proper surface preparation is essential for the success of any protective coating system. Before you begin ensure the area is free from any dust, oil, grease, old coatings and surface contaminants.

The preparation of steelwork prior to painting generally falls into two main areas; that of degreasing and the removal of rust and scale.

All surfaces to be painted should be clean, dry and free from loose and flaking material, dust, grease and millscale, etc.

Prime bare surfaces with Palatine Anti-Corrosive Metal Primer or Palatine All Purpose Primer / Undercoat in accordance with our recommendations

For non-ferrous metals use Palatine Fast Dry etching primer.

Rub down previously gloss painted surfaces with fine waterproof abrasive paper and rinse thoroughly.

Mixing

Stir the paint with a drill stirrer or wooden baton at least 2” wide. Continue to stir during application.

Application

Best results are obtained in warm (minimum 10°C), dry conditions.

Mix thoroughly for approximately 2 minutes using a drill stirrer. A wooden batten at least 25mm wide is also ideal.

Apply an even coat using a brush, short to medium pile roller on smooth surfaces and a long pile roller on textured surfaces

For spray application by either airless or conventional spray a dilution ration of no more than 10% is recommended with Palatine White Spirit by volume applying thin coats allowing each one to dry before applying subsequent coats.

Once dried, a second coat can be applied at full strength. This will prolong the life and performance of the coating.

Thinning and Cleaning: Use Palatine White Spirit.

If using more than one batch of the same colour, intermix before use

Preceding Coat

Prime bare surfaces with Palatine Anti-Corrosive Metal Primer or Palatine All Purpose Primer / Undercoat in accordance with our recommendations

For non-ferrous metals use Palatine Mordant Solution.

Subsequent Coat

A second coat is recommended for maximum protection.

Be the first to review “ArmourFlex UV Protection Oil”

You may also like…

Cladding Paint

Reviews

There are no reviews yet.