All Blogs

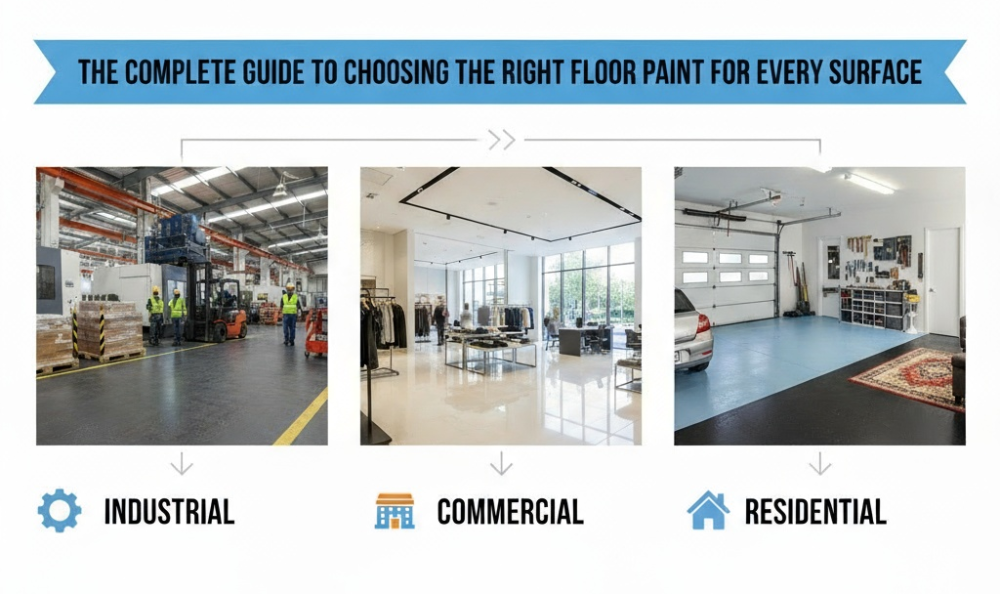

The Complete Guide to Choosing the Right Floor Paint for Every Surface: Industrial, Commercial & Residential Applications

Selecting floor paint isn’t just about colour—it’s about performance, safety, and lifetime cost. Whether you’re coating a warehouse, hospital corridor, school, or residential garage, the wrong system leads to premature wear, costly repairs, and avoidable hazards.

- Substrate: concrete, wood, metal, tarmac, mixed surfaces

- Traffic: from light domestic use to heavy forklift loads

- Environment: dry interiors, wet areas, chemical exposure, exterior conditions

Floor Paint Types Explained

Choosing the right floor paint starts with understanding your options. Each formulation offers distinct advantages tailored to specific environments, traffic patterns, and performance requirements.

Carbotread Polyurethane Floor Paint

Single-Pack Convenience for Demanding Environments

Best for: Warehouses, light-to-medium industrial floors, garages, and commercial spaces needing fast turnaround.

- Single-pack – no mixing, less waste

- Touch dry in around 2 hours – minimises downtime

- Tough polyurethane chemistry – excellent abrasion resistance for wheeled traffic

- Typical coverage: 10–12 m² per litre (substrate dependent)

- Full cure: approximately 7 days for maximum hardness and durability

Carbotread withstands minimal chemical exposure and maintains its finish under consistent industrial and commercial use.

2 Pack Epoxy Floor Paint

Two-Pack Chemical Resistance for Heavy-Duty Applications

Best for: Heavy industrial floors, forklift traffic, chemical processing, automotive workshops, and plant rooms

- Frequent exposure to oils, hydraulic fluids, solvents, acids, and alkalis

- Heavy point loads from forklifts, pallet trucks, and machinery

- Environments where long-term durability and chemical resistance are non-negotiable

Epoxytread Single Pack Epoxy Floor Paint

Single-Pack Epoxy Convenience for Tough Floors

- Single-pack epoxy technology – no mixing ratios or pot life to manage

- Improved durability over standard floor paints for light-to-medium industrial and commercial traffic

- Good resistance to oils, fuels, and common workshop contaminants

- Easy application by brush or roller on properly prepared concrete and other suitable substrates

- Attractive, hard-wearing finish that brightens and tidies working environments

Carbogrip Anti-Slip Floor Paint (Carbogrip, Stepgrip)

Safety Compliance for High-Traffic Areas

- Stepgrip (exterior):

Designed to withstand UV exposure, freeze–thaw cycles, and weathering. Ideal for loading bays, ramps, external steps, and outdoor walkways. - Carbogrip (interior):

Focuses on chemical resistance and ease of cleaning for warehouses, kitchens, production floors, and internal staircase

Chlorinated Rubber Floor Paint

Fast-Drying Chemical Resistance

Chlorinated rubber coatings combine rapid drying times with excellent chemical resistance, making them ideal for swimming pools, chemical storage areas, and industrial facilities requiring quick turnaround.

- Touch dry in 30–60 minutes – multiple coats in a single day

- Resistant to chlorine, acids, alkalis, and water

- Particularly suitable for aquatic facilities and chemical processing environments where conventional paints fail

Wood Floor Paint & Varnish

Protective Beauty for Timber Surfaces

- Polyurethane varnish: Transparent protection that enhances natural grain – ideal for high-quality timber floors in homes, offices, and retail.

- Opaque wood floor paint: Full colour coverage to hide imperfections and create uniform finishes in workshops, storage areas, and contemporary interiors.

Choosing Floor Paint by Substrate

Your substrate dictates everything. Even the highest-quality floor paint will fail without proper surface compatibility and preparation. Here’s how to match Palatine’s solutions to your specific flooring material.

| Substrate | Key Challenges / Considerations | Preparation Essentials | Recommended Palatine Solutions | Common Mistakes to Avoid | |

|---|---|---|---|---|---|

| Concrete | Porous, alkaline; moisture issues; prone to contamination and laitance | – Allow new concrete to cure ≥ 28 days – Test for moisture / DPM – Degrease, remove laitance (mechanical or acid etch) – Neutralise & fully dry after etching – Prime porous/dusty surfaces with penetrating/epoxy primer | – Light–medium traffic: Carbotread polyurethane – Heavy industrial/chemical: Epoxytread 2-pack epoxy – High slip risk: Carbogrip / Stepgrip over compatible base | – Coating over damp/green concrete – Skipping primer on porous/dusty slabs – Poor degreasing – Insufficient surface profile | |

| Wood | Movement (expansion/contraction); UV and weathering externally; need for flexibility | – Ensure sound, dry timber – Sand/abrade for key – Remove dust and contamination – Use exterior-grade systems outdoors | – Interior wood floor paints & polyurethane varnishes (gloss/satin/matt) – Stepgrip anti-slip for stairs, ramps, decking | – Using rigid, non-flexible coatings – Using interior products externally – Ignoring movement and moisture effects | |

| Tarmac / Asphalt | Ageing, loss of oils, loose aggregate; traffic and weather exposure; movement and flexing | – Clean thoroughly – Remove loose material – Ensure surface is dry and structurally sound | – Carbomac Tarmac Restorer to rejuvenate aged tarmac, restore flexibility, bind aggregates, and refresh appearance |

|

|

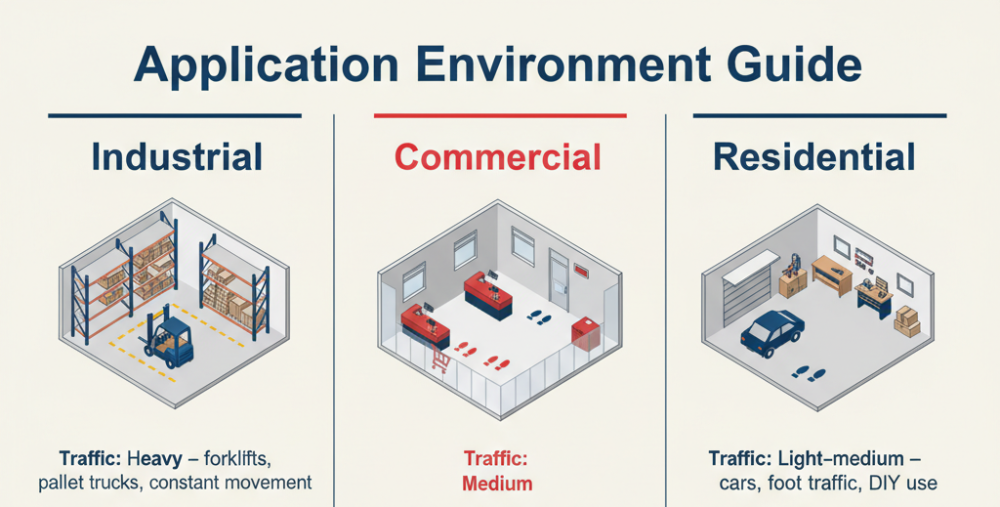

Application Environment Guide

Matching floor paint to your specific environment ensures optimal performance, longevity, and return on investment. Here’s how to select the right Palatine solution for your space.

Surface Preparation & Application

Proper preparation determines coating success more than any other factor. Even premium floor paint fails on poorly prepared surfaces. Follow these critical steps for lasting results.

Acid Etching Concrete

Opening the Surface for Maximum Adhesion

Smooth, dense concrete prevents mechanical bonding. Acid etching creates a profile that allows coatings to grip effectively.

The Process: Mix hydrochloric acid (1 part acid to 3-4 parts water—always add acid to water, never reverse). Apply to clean, dry concrete and scrub with stiff brushes while the solution fizzes. This chemical reaction removes laitance and opens pores. Neutralize with diluted ammonia or sodium bicarbonate solution, then rinse thoroughly multiple times. Allow complete drying (24-48 hours minimum) before coating.

Safety First: Wear protective equipment—goggles, gloves, respirator, and protective clothing. Ensure adequate ventilation. Acid etching is aggressive but essential for proper adhesion on dense concrete.

Repairing Damaged Floors

Fix Before You Coat

Cracks, spalls, and surface damage telegraph through coatings and worsen over time.

Coldcrete for Structural Repairs: This rapid-setting cementitious repair compound fills cracks, holes, and damaged areas in concrete floors. Its fast cure allows same-day coating in many cases. Clean out loose material, dampen the repair area, apply Coldcrete, and feather edges smooth.

Epoxy Patch Repair: For chemical-resistant repairs or areas requiring maximum strength, epoxy patch compounds provide superior bonding and durability. These two-component systems cure harder than surrounding concrete, creating permanent repairs that won’t crack or shrink.

Application Methods

Choosing Your Tools

Brush Application: Ideal for edges, corners, and small areas. Provides excellent material penetration but slower coverage.

Roller Application: The most common method for floor coatings. Use short-nap rollers (5-10mm) for smooth surfaces, longer naps for textured substrates. Maintain wet edges to prevent lap marks. Work in manageable sections.

Temperature Considerations

Environmental Limits

Apply floor coatings between 10-25°C for optimal performance. Cold temperatures slow curing dramatically—below 10°C, coatings may not cure properly. High temperatures accelerate drying, reducing working time and potentially causing application defects.

Substrate Temperature Matters: Concrete must be at least 3°C above dew point to prevent moisture condensation during application, which causes adhesion failure and surface defects.

Preparation isn’t glamorous, but it’s the difference between a floor that lasts decades and one that fails within months.

Specialist Solutions

Beyond standard floor coatings, Palatine offers targeted products that solve specific challenges and enhance functionality.

Line Marking

Organise, Direct, and Protect

Clear floor markings improve safety, optimise workflow, and ensure regulatory compliance in industrial and commercial environments.

Road Marking Paint: Durable, fast-drying formulations designed for vehicle traffic on roads, car parks, and loading areas. High-opacity pigments ensure visibility in all conditions. Available in standard safety colours—white, yellow, red, and blue—for traffic control and hazard designation.

Warehouse Floor Marking: Define pedestrian walkways, forklift routes, storage zones, and hazard areas. Proper marking reduces accidents, improves efficiency, and demonstrates safety compliance during inspections. Use contrasting colours against floor coating for maximum visibility.

Spray vs Brush Application: Airless spray equipment delivers crisp, professional lines quickly—ideal for long runs and large projects. Brush application suits smaller jobs, touch-ups, and facilities without spray equipment. Both methods produce durable results when properly applied.

Stencils and Equipment: Pre-cut stencils ensure consistent lettering and symbols—arrows, numbers, safety warnings, and parking designations. Line marking machines with guide wheels create perfectly straight lines without masking tape, dramatically improving productivity on large marking projects.

Problem-Solving Products

Addressing Substrate Challenges

Not every floor is perfect. Palatine’s specialist products overcome common substrate problems that would otherwise prevent successful coating.

Damp Proof Membrane (DPM): When concrete lacks an effective moisture barrier, rising damp destroys conventional coatings. Specialized DPM coatings create an impermeable barrier, blocking moisture migration and allowing successful topcoat application on problematic substrates. Essential for ground-floor slabs in older buildings without modern damp-proofing.

Damp-Tolerant Primers: Some substrates retain moisture despite best efforts. Moisture-tolerant epoxy primers bond to slightly damp concrete, expanding application windows and enabling coating in challenging conditions. These primers prevent the blistering and delamination that moisture causes with standard products.

Floor Repair Systems: Coldcrete rapid-setting cement and epoxy patch repair compounds restore structural integrity before coating. Address all damage first—coating over cracks and holes guarantees future failure.

Dust Sealers (2K Epoxy): Porous, dusty concrete sheds particles constantly, contaminating products and creating housekeeping nightmares. Two-pack epoxy dust sealers penetrate deep, binding loose particles and creating a hard, dust-free surface. These clear sealers provide protection without changing appearance—ideal when decorative coatings aren’t required but dust control is essential.

Specialist products transform impossible projects into successful installations.

Frequently Asked Questions

How long does floor paint last?

Longevity depends on traffic intensity, substrate preparation, and product selection. Properly applied polyurethane floor paint lasts 3-5 years in moderate traffic environments. Heavy-duty epoxy systems in industrial facilities can exceed 10 years with proper maintenance. Light-traffic residential garages may see 7-10 years from quality coatings. Poor preparation dramatically reduces lifespan regardless of product quality.

Can I paint over existing floor paint?

Yes, if the existing coating is sound, well-adhered, and compatible. Remove all loose, flaking, or contaminated paint. Degrease thoroughly and lightly sand to create mechanical adhesion. Test a small area first—some coatings don’t bond well to certain existing finishes. When in doubt, remove old paint completely for guaranteed adhesion.

What’s the difference between epoxy and polyurethane?

Epoxy offers superior chemical resistance, impact tolerance, and adhesion—ideal for heavy industrial use. It’s harder but less flexible, and can yellow under UV exposure.

Polyurethane provides excellent abrasion resistance, UV stability, and flexibility. It’s easier to apply (single-pack options available) and maintains colour better in sunlight. Best for moderate traffic and areas requiring aesthetic durability.

Choose epoxy for chemical exposure and extreme conditions; polyurethane for general-purpose durability and ease of use.

Do I need a primer?

Usually yes. Prime porous, dusty, or previously unpainted concrete to improve adhesion and prevent outgassing. New concrete benefits from penetrating primers that consolidate the surface. Epoxy topcoats require compatible primers for proper bonding. Dense, well-prepared concrete with good surface profile may not require priming—consult product technical data sheets.

How do I calculate coverage?

Check the product’s technical data sheet for coverage rates (typically 8-12 m² per litre). Measure your floor area in square meters. Divide area by coverage rate, then multiply by number of coats required (usually 2). Add 10-15% for waste and surface irregularities. Porous substrates consume more paint—reduce expected coverage by 20-30%.

What’s the best floor paint for heavy traffic?

Two-pack epoxy systems (Epoxytread) deliver maximum durability for forklift traffic, heavy machinery, and industrial abuse. For slightly lighter commercial traffic, polyurethane (Carbotread) offers excellent wear resistance with easier application. Always match product to actual traffic intensity—over-specification wastes money, under-specification guarantees premature failure.

Make the Right Choice for Your Floor

Selecting floor paint isn’t guesswork—it’s matching proven solutions to your specific substrate, traffic demands, and environmental conditions. Whether you’re protecting an industrial warehouse, refreshing a commercial space, or upgrading your garage, Palatine offers engineered coatings that deliver lasting performance.

Key selection criteria matter: Understand your substrate requirements, assess traffic intensity honestly, consider chemical exposure and environmental factors, and never compromise on surface preparation.

Expert Support Available

Need guidance? Palatine’s technical team provides free consultation on product selection, surface preparation, and application methods. We help you specify the right solution the first time.

Try before you commit: Sample pots available for colour approval and application testing.

Contact Palatine today – Transform your floor with confidence, backed by decades of coating expertise and proven performance.