All Blogs

Pipe Identification Paint Standards: BS 1710 Compliance Guide for UK Facilities

Why this works:

✅ Targets compliance-driven searches with high purchase intent

✅ Positions you as the technical expert in a niche but essential market

✅ Appeals to facilities managers, HSE officers, and industrial contractors

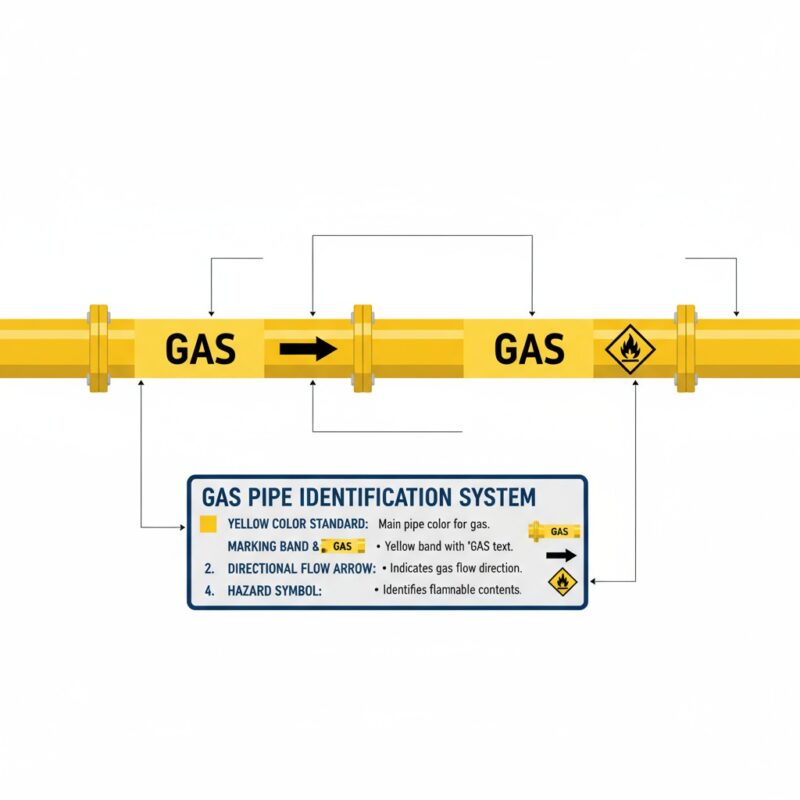

UK Pipe Identification Regulations (BS 1710:2014)

- Prevent accidents and operational errors

- Enable rapid identification during emergencies

- Facilitate maintenance and repair work

- Ensure regulatory compliance across industries

- Standardise identification across different facilities

Core Colour Code System

| Colour | Pipe Contents | BS4800 Reference | |

| Green | Water (except fire-fighting) | 12 D 45 | |

| Blue | Air |

|

|

| Yellow Ochre | Gases (except air) |

|

|

| Orange | Acids and Alkalis |

|

|

| Red | Fire-fighting equipment | 04 E 53 | |

| Black | Drainage and Sewage |

|

|

| Brown | Mineral, Vegetable, Animal Oils |

|

|

| Purple/Violet | Unidentified/Other Liquids | 22 C 37 | |

| Silver Grey | Steam | 10 A 03 | |

Why Proper Pipe Identification Prevents Accidents and Improves Efficiency

Accident Prevention Benefits

1. Prevents Hazardous Material Exposure

- Workers may open the wrong valve, releasing toxic gases, corrosive chemicals, or scalding steam

- Maintenance staff drilling into unmarked pipes can puncture high-pressure lines

- Contractors unfamiliar with the facility may inadvertently access dangerous systems

- Instant visual recognition of pipe contents before any work begins

- Color-coded warnings alert workers to hazardous materials

- Hazard symbols provide immediate danger awareness

- Workers can verify pipe contents without consulting outdated drawings

2. Reduces Cross-Contamination Risks

- Food and beverage production (allergen control)

- Pharmaceutical manufacturing (product purity)

- Healthcare facilities (sterile vs. non-sterile water)

- Drinking water systems (potable vs. non-potable)

- Drinking water with industrial process water

- Clean steam with contaminated condensate

- Food-grade ingredients with cleaning chemicals

3. Prevents Fire and Explosion Hazards

- Natural gas lines mistaken for air lines

- Fuel oil systems confused with water systems

- Oxygen lines (which accelerate combustion) misidentified

- Flammable gases or vapours

- Combustible liquids

- Oxygen-enriched atmospheres

- Red banding on flammable content pipes provides instant warning

- Workers can identify and isolate hazardous lines before hot work

- Emergency responders know which pipes to prioritize during fires

4. Protects Against Thermal Injuries

- Steam pipes (often 150-200°C)

- Hot water systems

- Thermal oil circuits

- Liquid nitrogen (-196°C)

- Refrigerant lines

- Cryogenic gas systems

- Severe burns from steam or hot surfaces

- Frostbite from cryogenic systems

- Thermal shock injuries

- Silver grey colour for steam with temperature warnings

- “Hot Surface” or “Extreme Cold” supplementary labels

- Insulation marking to prevent accidental contact

5. Emergency Response Effectiveness

- Firefighters need immediate identification of fire suppression systems (red pipes)

- Must avoid cutting into gas lines or chemical pipes

- Need to locate water supplies quickly

- Emergency teams must identify the source pipe immediately

- Isolation valves need to be located fast

- Hazard information guides appropriate response measures

- In hospitals, medical gas identification prevents fatal errors

- Oxygen, nitrous oxide, and medical air must be unmistakable

- Wrong gas administration can be lethal.

Operational Efficiency Benefits

1. Faster Maintenance and Repairs

- Maintenance staff spend 15-30 minutes per job tracing pipes through drawings

- Must physically trace pipes through ceilings, walls, and plant rooms

- Risk of working on wrong system, wasting time and resources

- Need to verify pipe contents through testing or process isolation

- Instant identification saves 20-40 hours per month in a typical facility

- Technicians can prepare correct tools and materials before starting

- Reduced troubleshooting time when systems malfunction

- Faster isolation of correct systems during repairs

2. Reduced Downtime

- Quickly identify which valves control which systems

- Minimize unnecessary shutdowns of unaffected systems

- Faster restoration after maintenance

3. Improved Troubleshooting

- Quickly trace flow paths through complex systems

- Identify interconnections and dependencies

- Locate isolation points for testing

- Verify correct system operation

- Multiple water circuits (chilled, hot, potable, process)

- Various compressed gas systems

- Chemical feed systems

- HVAC distribution

4. Contractor and New Employee Onboarding

- Experienced staff retire, taking facility knowledge with them

- Contractors arrive with no site familiarity

- New employees need months to learn complex systems

- Self-documenting systems that don’t rely on institutional knowledge

- Immediate orientation for contractors and new staff

- Reduced supervision requirements

- Lower training costs and faster competency development

5. Inventory and Spare Parts Management

- Knowing exact pipe materials and sizes enables accurate spare parts stocking

- Reduces emergency procurement of wrong parts

- Minimizes inventory carrying costs

- Enables predictive maintenance planning

- Stock appropriate valve types and sizes

- Ensure gasket material compatibility

- Plan replacement schedules effectively

6. Energy Efficiency and System Optimization

- Energy audits to identify inefficient systems

- Heat loss identification on steam and hot water systems

- Compressed air leak detection programs

- Optimization of flow rates and pressures

7. Regulatory Compliance and Audit Readiness

- Health and safety inspectors can quickly verify compliance

- Insurance assessors can evaluate risk more accurately

- Internal audits proceed faster with clear documentation

- Non-compliance fines can reach £20,000-£100,000+

- Insurance premium reductions for well-managed facilities

- Faster permit approvals for modifications

8. Project Planning and Modifications

- Engineers can quickly assess existing infrastructure

- Accurate as-built documentation is immediately visible

- Reduced need for invasive investigation

- Faster, more accurate project quotes from contractors

9. Asset Management and Lifecycle Planning

- Visual inspection programs identify deteriorating pipes faster

- Maintenance history can be tracked by system

- Replacement priorities become evident

- Capital planning is more accurate

- High-risk systems (acids, gases) inspected more frequently

- Low-risk systems (drainage) on extended schedules

- Resource allocation optimised

Pipe Identification Paint Product Range

- Green – Water (except fire-fighting)

- Blue – Air

- Yellow Ochre – Gases (except air)

- Orange – Acids and alkalis

- Red – Fire-fighting equipment

- Black – Drainage and sewage

- Brown – Oils (mineral, vegetable, animal)

- Purple/Violet – Unidentified or other liquids

- Silver Grey – Steam

- White – Vacuum systems

- Specifically formulated for pipe identification

- Durable, long-lasting finish

- Suitable for interior and exterior use

- Complies with UK safety standards

- Professional finish

- Multiple size options available

2. Paint for Copper Pipes

- Superior adhesion to copper surfaces

- Protects against oxidation and corrosion

- Professional finish

- Can be overcoated with identification colours

- Ideal for exposed copper pipework

3. Coo-Var Heat Resistant Paint Black

- Heat resistant formulation

- Suitable for pipes carrying hot fluids or steam

- Black finish

- Withstands elevated temperatures

- Durable enamel finish

Application Methods for Different Pipe Materials and Environments

Selecting the right pipe material can make or break your plumbing project. Whether you’re a contractor, engineer, or DIY enthusiast, understanding which pipe works best for your specific application saves time, money, and headaches down the road.

The 8 Essential Pipe Materials

Copper

Best for: High-end residential, commercial water supply, gas lines

Lifespan: 50-70 years

Why choose it: Durable, fire-resistant, naturally antimicrobial, and handles high pressure

Watch out: Expensive and can corrode in acidic water conditions

Galvanized Steel

Best for: Fire sprinkler systems, outdoor installations, gas distribution

Lifespan: 20-50 years

Why choose it: Strong, handles high pressure, excellent for outdoor use

Watch out: Heavy, prone to internal corrosion and scale build-up over time

Stainless Steel

Best for: Coastal areas, food processing, pharmaceutical applications

Lifespan: 75-100+ years

Why choose it: Superior corrosion resistance, handles extreme temperatures

Watch out: Most expensive option and requires specialised installation skills

HDPE (High-Density Polyethylene)

Best for: Underground municipal water, natural gas distribution

Lifespan: 50-100 years

Why choose it: Leak-free heat-fused joints, lightweight, earthquake-resistant

Watch out: Requires specialized fusion equipment

Cast Iron

Best for: Multi-story drainage, sound-sensitive installations

Lifespan: 75-100 years

Why choose it: Extremely durable, excellent sound dampening, fire-resistant

Watch out: Very heavy and expensive to install

How Long Will Your Pipes Last? Maintenance Schedules & Lifespan Guide

Your plumbing system is one of your property’s most critical—and expensive—infrastructure components. Understanding how long different pipe materials last and what maintenance they need can save you thousands in emergency repairs and water damage. Here’s your essential guide to pipe durability and care.

Expected Lifespan by Material

PEX: 40-50 years

Copper: 50-70 years (up to 100+ in ideal conditions)

Galvanized Steel: 20-50 years (highly variable)

Stainless Steel: 75-100+ years

HDPE: 50-100 years

Cast Iron: 75-100 years

What Shortens Pipe Life?

PEX

- Sunlight exposure (degrades rapidly)

- Rodent damage

- Improper crimp connections

Copper

- Acidic water (causes pinhole leaks)

- Electrical grounding through pipes

- Dissimilar metal connections

Galvanized Steel

- Internal rust and scale build-up

- Compromised zinc coating

- Poor water quality

Stainless Steel

- Wrong grade for environment (304 vs 316)

- Installation contamination

- High chloride exposure

Your Maintenance Schedule

Every Month (Quick Check)

- Look for visible leaks or corrosion

- Check for water stains on walls/ceilings

- Listen for unusual sounds (banging, whistling)

Every Year (Annual Inspection)

- Inspect all exposed pipes for damage

- Test shutoff valves and pressure relief valves

- Check pipe supports and hangers

- Verify insulation integrity

- Document water pressure changes

Every 2-3 Years

- Pressure test critical lines

- Video inspect underground drainage

- Professional evaluation of system performance

Every 5 Years

- Comprehensive professional inspection

- Water quality testing and analysis

- Plan for upcoming replacements

- Replace aging valves and fixtures

Every 10 Years

- Complete system audit

- Code compliance evaluation

- Long-term replacement planning

Material-Specific Maintenance Tips

PEX: Protect from sunlight at all times. Test crimp connections with go/no-go gauge. Watch for rodent activity.

Copper: Test water pH annually (should be 6.5-8.5). Install dielectric unions between copper and steel. Monitor for green corrosion at joints.

Galvanized Steel: Monitor water flow and pressure quarterly. Plan replacement if system is 30+ years old. Internal corrosion is irreversible.

Stainless Steel: Use only stainless tools during maintenance. Remove carbon steel contamination immediately. Inspect welds annually.

HDPE: Minimal maintenance required. Protect from mechanical damage during excavation. Inspect fusion joints annually.

Cast Iron: Verify supports regularly (very heavy material). Video inspect drainage lines every 3 years. Repair coating damage promptly.

Red Flags: When to Call a Professional Immediately

- Active leaking at joints or pipe body

- Bulging or deformed pipe sections

- Discoloured or rust-coloured water

- Sudden pressure loss throughout system

- Visible cracks or splits

- Strong sewage odours

Warning Signs: Schedule an Inspection Soon

- Gradual pressure decline over weeks

- Intermittent leaks that stop and start

- Unusual sounds in pipes

- Slow drains in multiple locations

- Unexplained increase in water bills

- Water stains appearing on surfaces

The Cost of Neglect vs. Prevention

Annual Preventive Maintenance:

- Residential: £200-500

- Commercial: £1,000-5,000

- Industrial: £5,000-50,000+

Cost of Failure:

- Emergency repairs: 3-5x planned maintenance cost

- Water damage: £5,000-50,000+

- Business interruption: Often exceeds repair costs

- Insurance impacts: Higher premiums or denied claims

The Bottom Line: Proper maintenance extends pipe life by 20-40% and prevents 80-90% of catastrophic failures. For a £10,000 piping system, spending £300-500 annually on maintenance can prevent £50,000+ in damage and replacement costs.

Extend Your Pipe Lifespan: Pro Tips

Manage Water Quality

- Keep pH between 6.5-8.5 for metal pipes

- Install water softeners in hard water areas

- Use sediment filters at main entry

- Install pressure regulators to prevent surges

Protect Your Investment

- Insulate pipes in extreme temperature areas

- Support pipes at manufacturer-recommended spacing

- Allow for thermal expansion on long runs

- Shield pipes from UV exposure and mechanical damage

Plan Proactively

- Budget for replacement before failure occurs

- Replace sections during renovations

- Consider whole-system replacement for aging infrastructure

- Upgrade to more durable materials when replacing

When to Replace (Not Just Repair)

Consider full replacement when:

- System age exceeds 75% of expected lifespan

- Frequent repairs are becoming necessary

- Water quality issues stem from pipe degradation

- Building codes have changed requiring updates

Example: If your galvanized steel pipes are 35+ years old and you’re experiencing reduced flow and rusty water, it’s time to replace—not patch. Internal corrosion is progressive and irreversible.

Custom Formulation Options for Specialized Pipe Identification Requirements

While standard BS 1710:2014 compliant paints cover most industrial applications, many facilities face unique challenges that demand specialized paint formulations. Understanding when custom solutions are necessary can save significant time, money, and maintenance costs.

When Standard Formulations Fall Short

Certain environments push standard paints beyond their design limits, resulting in premature failure, safety risks, and costly repainting cycles.

Common challenging scenarios:

- Extreme temperatures (above 200°C or below -50°C)

- Aggressive chemical exposure (acids, alkalis, solvents)

- Specialized substrates (copper, stainless steel, plastics)

- High-abrasion or outdoor UV exposure

- Food-grade and pharmaceutical cleanroom environments

Specifying Custom Formulations

Information required for custom solutions:

Environmental Conditions:

- Operating temperature range (min/max)

- Chemical exposure (type, concentration, frequency)

- UV exposure level and moisture conditions

Substrate Details:

- Pipe material and surface condition

- Pipe diameter and accessibility

- Existing coating (if overcoating)

Performance Requirements:

- Expected service life

- Maintenance window constraints

- Compliance standards (BS 1710:2014, industry-specific)

- Application method (brush, spray, roller)

Cost Considerations

Custom formulations typically cost 20-60% more than standard paints (£15-25/litre), but deliver:

- Extended service life (2-3x longer)

- Reduced maintenance frequency

- Lower total cost of ownership over 10 years

- Avoided downtime from premature failure

- Compliance assurance in regulated environments

ROI: Custom formulations often deliver 200-400% return over 10 years through reduced maintenance cycles and avoided failures.

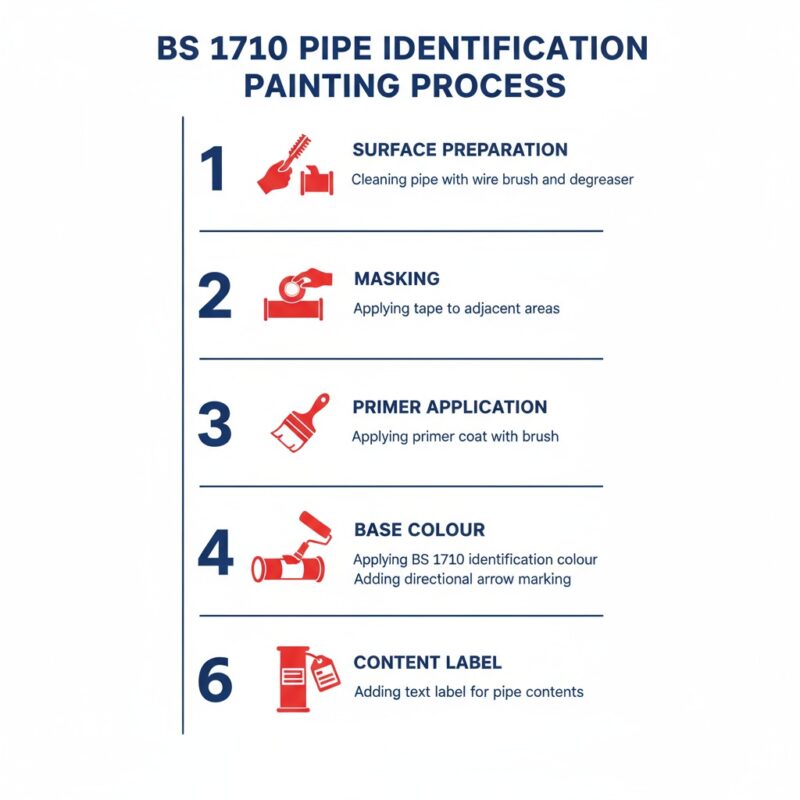

Application Best Practices

Surface Preparation

- Solvent wipe or alkaline wash

- Degreasing (essential for non-ferrous metals)

- Light sanding (180-240 grit)

- Substrate-specific primers where required

- Ensure surface is completely dry

Application Conditions

- Temperature: 10-25°C (follow manufacturer specs)

- Humidity: <85% relative humidity

- Apply specified film thickness

- Adhere to minimum/maximum recoat windows

Curing Requirements

- Heat cure for high-temperature coatings

- Proper mixing ratios for two-component systems

- Allow full cure time (7-14 days for some systems)

Surface preparation

Carboxide Anti-Corrosive Metal Primer – Product Overview

Carboxide Metal Primer is an anti-corrosive zinc phosphate metal primer paint designed for iron and steel surfaces. Based on alkyd resin with modified zinc phosphate and binding pigments, it provides long-term protection against rust and corrosion.

Key Features

- Anti-corrosive protection with zinc phosphate formulation

- Versatile compatibility – works with various topcoats

- Fast-drying – surface dry in 3 hours

- Multiple colour options – Grey, Red, and White

- Excellent coverage – 12-14m² per litre

- Proven performance – works even on surfaces beginning to rust

Why Use Anti-Corrosive Primer?

Both iron and steel are prone to rust when exposed to air and moisture. Rust forms when iron reacts with oxygen and water, creating surface coating that leads to corrosion if untreated.

Carboxide Metal Primer provides longer-term protection against rust and corrosion, with customers reporting effectiveness even on surfaces already showing rust.

Safety and Security Paints